Retail Display Design

Our dedicated and highly creative retail display design team provide the best solutions for your brand’s POP & POS requirements.

Decades of experience in creating Retail Display Design and Point of Sale and Point of Purchase units. We design eye catching and modern displays keeping in touch with effective concepts, colours and designs that really work.

Our design team consider all the factors of what makes a great display. It has to stand out against the competition, yet fit in with the store environment. It has to have a clear message of what the products benefits and differentiators are, be durable, and consideration to where the display will be placed within the retail environment.

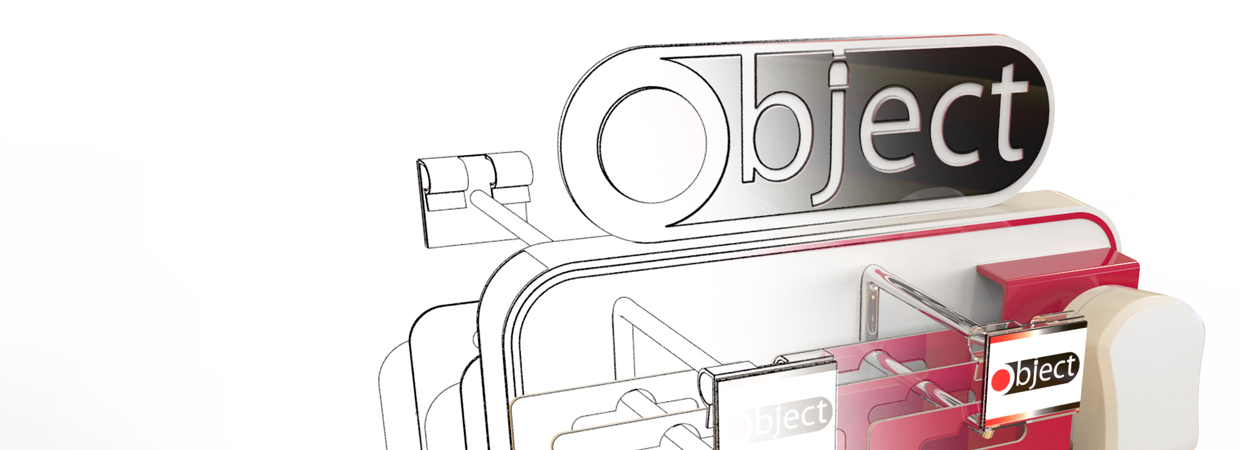

Our design process (shown below), starts from initial contact with our clients but we can also work on designs supplied by our clients or simply take approved work and provide manufacturing and installation services.

Understanding the Design Process

Concept: Our design team review the information gathered from the information provided to decide how to connect with the target audience, how to demonstrate the benefits of the product and if an interactive or video display would be appropriate. Our design team will create design sketches and/or rough digital images to demonstrate initial concepts to the client.

3D CAD Model: Once concepts have been reviewed, our design team produce detailed computer models to help the client get a better understanding of the display, how their products will be mounted, and an idea of what it may look like in the retail environment. During this stage, elements such as materials, size and environment will be carefully considered to make the display look as realistic as possible. The size of the display stand and environment determine what type of display it will be, such as a free standing display, a counter display, a wall mounted display etc. It may also be a specific type of display such as a clothing display, footwear or golf display for example.

Costing: Once the computer model has been approved, the price of building the prototype and production run information is passed onto the client. This may result in some changes to the display in terms of materials, size or other minor adjustments. This is reviewed and re-costed

Prototype: A design prototype is then manufactured and tested with the clients products. This is then shipped to the client for review and following final approval it moves to the full production run stage.

Production: The approved prototype is made into a full scale production run. We are also able to offer delivery and installation project management services to ensure the displays will provide maximum customer exposure with professional installation.

Design FAQs

Reasons to choose Adglow?

- We can help get your design off the ground and into production, on time and on budget.

- If you already have your designs and need a manufacturer?

- If your current quote for your design is too expensive. Why not give us a try?

- We have over 50 years experience working in multiple materials.

- We are a global business with manufacturing facilities in the UK, EU and ASIA.

Materials

Adglow work in numerous materials, some of which include:

- Acrylic

- Timber

- Metal

- Injection/Resin Moulding

- Die Casting

- Press work

Project Gallery

If you need a little inspiration, or, you’re after something specific – head on over to our Project Gallery area, where you can browse images of previous projects we have undertaken.

If anything catches your eye – please feel free to chat to us online, leave an enquiry, or pick up the phone! We would be happy to speak to you in greater detail about any requirements you may have!